|

No. |

Product name |

Image |

Application function |

Maximum annual output |

|

|

1 |

Automatic terminal machine |

Hukun6000 |

|

This machine is a fully automatic cutting, end, testing and immersion tin machine. It realizes fully automatic production of products through intelligent control system, machine vision system and robot integrated operation system. It is easy to operate and has high product pass rate. An automatic device essential for the production of antenna harnesses. |

180 |

|

2 |

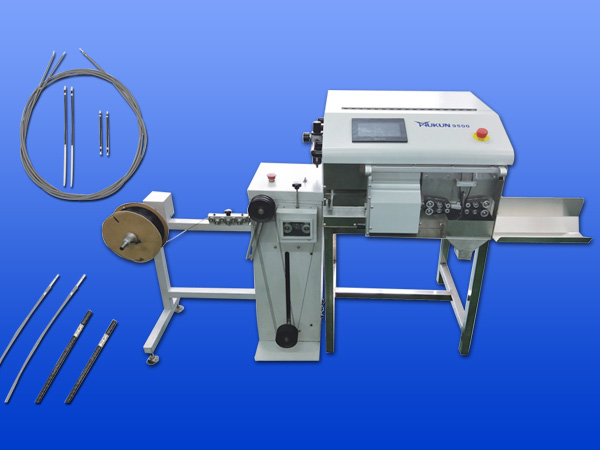

Automatic immersion tin machine |

Hukun6100 |

|

This machine is a fully automatic control of coaxial cable processing automation. Its function is mainly automatic cutting of coaxial cable and double-end automatic immersion tin. It is mainly used in antenna wire harness manufacturing enterprises. It realizes simple operation through human-machine interface, with strong function, wide compatibility and high product straight-through rate. |

150 |

| 3 |

Automatic double head terminal machine |

Hukun7000 |

|

This machine is a fully automatic control coaxial cable processing automation. This equipment realizes automatic automatic cutting machine, double-end automatic terminal machine riveting, automatic performance testing, automatic appearance inspection automatic machine. High quality products are achieved through a full computer control system. |

80 |

| 4 |

Fully automatic FPC bonding equipment |

Hukun8000 |

|

This equipment provides a fully automated device capable of accurately positioning safe and high-efficiency production in the NFC antenna production process; it is a combination of manufacturing technology, machine, motion control, machine vision, robot integration, lean and many other advanced technologies. Automation equipment. The device realizes the functions of automatic feeding, automatic tear film, automatic visual positioning, FPC automatic suction, robot automatic fitting, automatic network analyzer testing, automatic appearance detection, etc., which improves production efficiency. |

50 |